Six months after its founding, SMR startup Deep Atomic has revealed a reactor design concept that’s sized especially for data center customers. The company said last week that it would focus its energy (no pun intended) on potential data center customers by building tailor-made reactors.

“The data center energy demand peak and the peak interest has really only been in the past six to nine months,” Gerhard Maritz, Deep Atomic COO, told Ignition. “All the previous SMR developers were developing SMRs, but not specifically for data centers. The market opportunity was never there. And we’ve gone and said, ‘OK, what does the market want?’ And tried to design something for that need, rather than the other way around.”

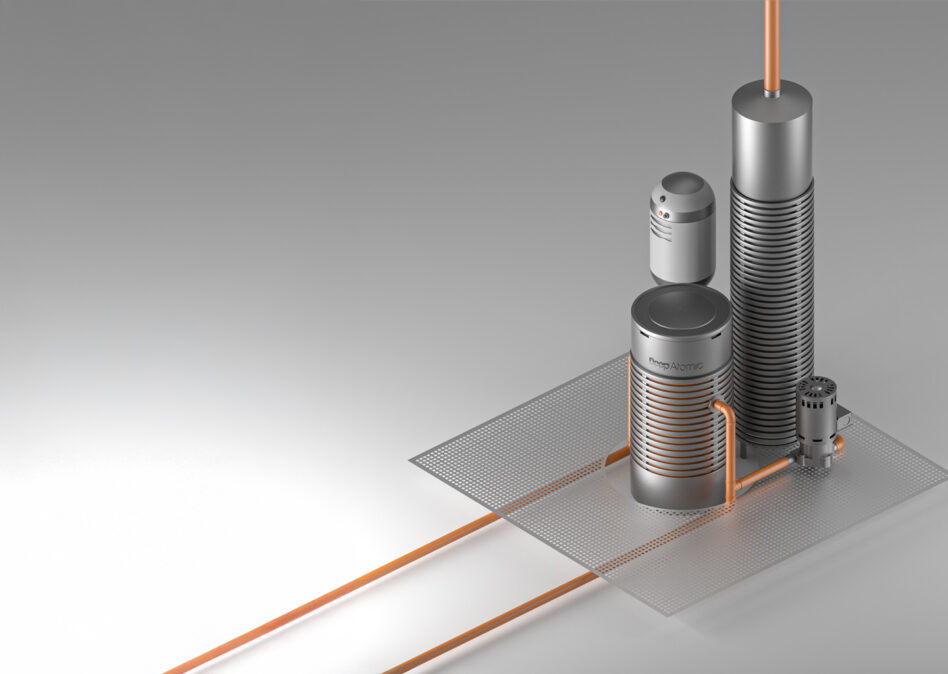

The result is a reactor that sits in the sweet spot between the microreactors and larger SMR designs being built today.

- Deep Atomic’s concept is the MK60, a 60 MW light water reactor with 60 MW of cooling.

- It’s also modular, and customers can choose to scale capacity to 1 GW or more by linking units together.

“This idea of tri-generation—we’re making cooling, electricity, and heat—while it’s been around in other industries, like combined cycle, gas generation, things like that, no one’s really talking about it in nuclear, and it’s just a really obvious application for SMRs,” Deep Atomic engineering lead Freddy Mondale told Ignition.

An eye for scale: The ability to manufacture reactors easily and reliably was an important factor in Deep Atomic’s initial design process. The reactor had to be small and simple enough to be easily built and deployed, but big enough to be economically feasible based on what’s already available in the nuclear fission sector.

“We’re betting that 60 MW is the sweet spot where we can still take advantage of economies of series and a factory-built environment, and we do still get some economies of scale,” Mondale said.

Speed demons: Getting to market fast is also a top priority for Deep Atomic. The light water design was picked in part to simplify the supply chain and regulatory process, including NRC approval.

“We’re even willing to pay a little bit more for a less efficient design or something clunkier, if it means that we can get to market with more certainty, more quickly,” Mondale said. “We’re applying that, not only in the design and the selection of suppliers and components themselves, but also in the regulatory process.”

Lead Reporter of Ignition