First Light Fusion is going through changes.

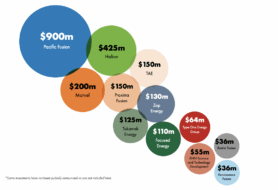

Until recently, the fusion developer planned to build a fusion plant of its own, but a few weeks ago announced it would take a different tack. Instead of pursuing a commercial fusion machine, First Light will commercialize its amplifier technology to support the burgeoning fusion sector.

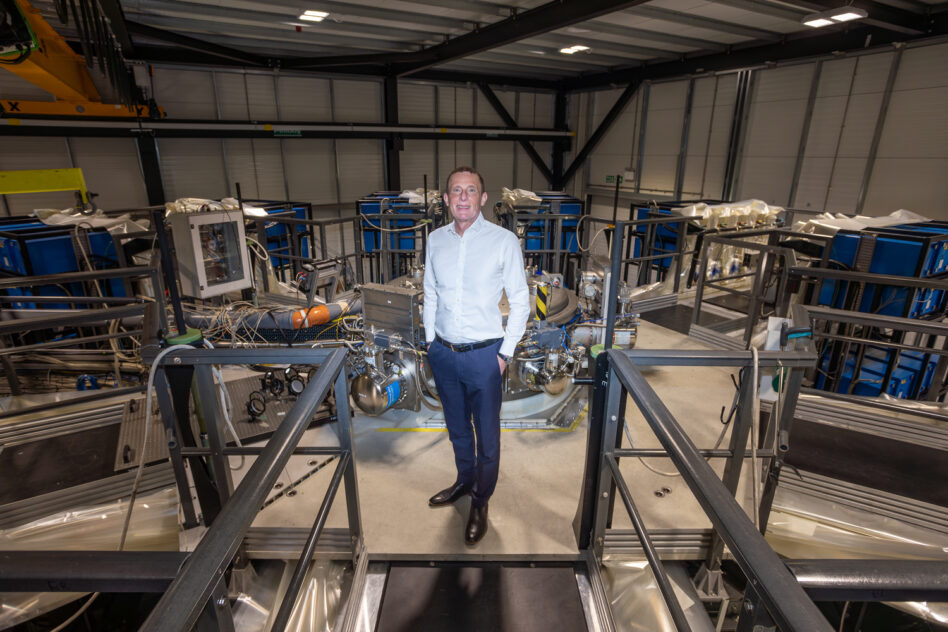

“If the pursuit is to make commercial fusion a reality, we should be behind that pursuit,” the company’s new CEO, Mark Thomas, told Ignition. “If we get there faster by leveraging our technology, let’s go down that pathway.”

First Light Fusion brought on Thomas, an energy industry vet, to usher the company through this transition. Thomas hails from Rolls-Royce, where he worked on aerospace-related programs, and ran an aerospace company for a decade before switching to fusion.

This interview has been edited for length and clarity.

Ignition: You’re newly appointed the CEO of First Light Fusion. What led you to the fusion sector and to First Light?

All my career, I’ve been driven by a sense of pursuit. Everything I’ve done, I’ve felt, needs to have a good, strong sense of purpose—solving problems, working in teams with smart people, hopefully making a difference to the world. So I did about 35 years all in the aerospace, defense, and tech sector related to aerospace and defense. 25 years of Rolls Royce, 10 years of the private technology business, and it was really life-defining experiences working on really important aviation projects that have changed the world, and then growing a technology business. Honestly, I thought I wouldn’t get the opportunity to have those experiences again.

I hadn’t looked in great detail at the fusion sector, but I was encouraged to take a look. And when I took a look, it really thrilled me. And there’s just so much to be excited about. It was just thriving, you know, with incredible innovation.

There was a degree of serendipity about it—right time, right place—but I feel now like I felt when I first stepped into the space sector a decade ago, which is like, “How did I not know that this incredible community was working so hard to make this happen?” Looking beyond the headlines to see what was really going on was really insightful and sort of exhilarating.

What do you mean by looking beyond the headlines?

Let me give you an example from space. To the general public, the thing about space is exploring other planets and astronauts in orbit. But then when you get inside the sector, you see there’s just a tremendous amount going on in terms of satellites, comms, AI, innovation in every sense, manufacturing advances in technologies across a wide spectrum, connection to other sectors. Yet there’s immediately benefits to life on Earth. In fusion, we see lots of the same things. You see the common desire and drive to make commercial fusion a reality, to really make sure that as a clean, viable, reliable and available source of power, energy for the planet, but taking the credible capability being developed into other areas and benefit in other areas. So it has a very familiar feel about it to me in that sense. And I think if you were in the general public, you just wouldn’t know that.

From your perspective, what are the biggest challenges in the short term that the fusion industry has to tackle?

So you can see that already that the industry is going down two clear pathways: one around magnetic confinement fusion, one around the inertial fusion energy approach. That’s interesting, because we’re developing suites of technologies and capabilities on these pathways, and there’s some big infrastructure challenges down the road, some big actual engineering challenges to solve, but the science is sound.

For me, it’s about putting together the right teams to collaboratively go and solve those challenges. Bringing together the innovators with enabling technology, that’s where First Light would be with the organizations, be it public or private, to help them understand how to embark on large infrastructure projects and build plants and develop the schemes and that enable those to become viable prospects.

There are a number of common challenges. I mean, we’ve got to get yield up. We’ve got to get gain to a much higher level. So whether that’s done through lasers or pulsed power or magnetic confinement, we’ve got to get to the levels of gain or ignition that really needed to support a commercial plant.

First Light Fusion just made this announcement that rather than pursuing a fusion plant itself, it’s going to be acting as a supplier of the amplifier services and some other supporting technologies. What was behind that decision?

There’s probably a few things, in truth. One is, I think, lifting the lid on the company to understand what capability the company really had and how that would play into the market, and realizing that there was this real gem, this absolute sort of critical technology around amplifiers that was well understood, well developed, that could be deployed commercially. Bringing that to light, literally shining a light on that, saying, “This is really valuable as an enabling technology,” was one factor.

The other was learning lessons from other sectors. Look, we actually don’t need to do this all on our own, and we shouldn’t be trying to do this all on our own. We should understand how we play into that collaboration space in a smart way, leverage our strengths and accelerate plans for people who are building those big machines.We’ll get there faster if we do that than if we do it all on our own. If the pursuit is to make commercial fusion a reality, we should be behind that pursuit. If we get there faster by leveraging our technology, let’s go down that pathway.

It has other benefits. It means the capital requirements of the business are much less in terms of investment needs. You can commercialize now, so you can get a return on investment. Now, for the technology, there’s definitely benefits, but actually, I think the driving force was genuinely, how can we make fusion happen in the fastest, simplest way, is by leveraging this amplifier technology.

Was inbound demand for the technology a driving force, or are you going out now and selling to other fusion companies?

What we’ve been doing is working closely with national laboratories. One thing we did not want to do, and I did not want, is to be drinking our own bathwater. Saying, “Hey, we’ve got this great technology. Everyone’s going to love it. It will sell.” Working with prestigious national laboratories that are world-respected, world-leading, to validate those claims is a key step in that direction.

Consequently, we’ve had fusion companies leaning in to show great interest in the technology. There is, of course, some push as well. We can see what everyone’s doing in this space, particularly talking about the inertial fusion energy space. We can see the laser schemes being developed. We can see the electrical connection or pulse power schemes being developed. We can see the projectile based fusion approach, and we can see how we can help them, assist with those, reduce the complexity, simplify some of those plans and concepts. So that’s our push out to the market and our willingness to collaborate, work together.

I’m curious to hear more about the renewed capital requirements for the business. Will you still need to raise additional capital to grow, or can you rely on revenue from here on out?

Here in the UK, we have everything we need in one building. So of 80 people, 50 of those are scientists and engineers. We have all of the computational capability, high performance computing. We have our in-house precision manufacturing. We have our experimental facilities. So in terms of equipment, infrastructure, facilities, we’re set. We can do design simulation, manufacture, testing of amplifiers, and then serve the market.

We are raising money. In today’s world it’s kind of a continuum. We’ll never not take an opportunity to look at money raising. We do have really strong support from our existing shareholders, and I’m happy to say that we’re currently raising 20 million pounds, of which we’ve got a large amount of support from existing shareholders, but we are going to market to attract some new investors as part of it, who will be excited, hopefully, about this strategy shift and plans. And that seems to be the case.

Have you generated revenue from the amplifier business to date?

We have now taken our first commercial contract for amplifier development. This is for particular customers with particular needs, and we’re funded to develop amplifiers that meet their requirements. That market ranges from, obviously fusion companies in the inertial fusion space, to space, particularly around ballistic testing for space debris, and then just the broader, huge area of dynamic materials testing. Understanding how materials behave at extreme pressures and temperatures requires some of the world’s largest machines, the Z machine or NIF, to generate those conditions. We can go beyond that into defense in other areas, but those are the ones we have in play currently.

We’re funded to do some work on the space side, so we can take projectiles to the velocities that are equivalent to space debris in orbit. So that’s about 14 km per second, typically using gas guns. We’re enhancing the capabilities of gas guns that are used for ballistic testing.

In terms of production, what’s the timeline and capacity you have to produce these amplifiers?

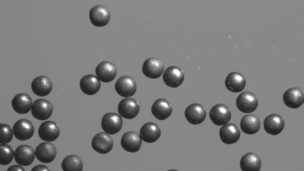

These amplifiers are about the size of a bottle top. The largest is the size of a bottle top, but they can be down to the size of a one carat diamond on a wedding ring. They’re made up of multiple layers of different density materials that are precisely shaped and manufactured. The manufacturing bit is all precision manufacturing, and we’re down to single digit microns. That does mean the amplifiers today are very high value, bespoke items. We put significant effort into the design simulation, testing, and manufacturing of these for high-end strategic customers. And that’s great, because that is definitely an area that will continue and is of keen interest—the strategic customers that have high-end, high-fidelity needs, and how we serve that market.

When you fly to the right, to the other end of the spectrum, you’re now talking about an operational fusion plant. When you do a shot, whether it’s a materials testing shot or a space debris shot or a fusion shot, the amplifier is completely consumed in the process. In a plant that’s going to happen every ten seconds. So the manufacturing journey that we’ll go on is going to take us in that direction of lower-cost, higher-volume amplifiers, and we’ll probably almost certainly do some of that through partnership or licensing with with other parties.

[via email: First Light Fusion has conducted over 1900 shots on its gas guns and pulsed power machines, 1/3 of which (more than 600) have incorporated the novel amplifier technology developed by the company.]

Are you restricted at all by bottlenecks in your supply chain to produce these amplifiers?

No, not at the moment, certainly not in these early years. As long as the material supply chain is there. And for some of them, it’s very standard materials, but obviously for the high-end applications, you get into more exotic materials.

Zooming back out, where do you see the opportunity for First Light Fusion within or outside the fusion sector in the coming years?

There’s an overwhelming feeling that we will get this job done. There’s a strong enough community that’s smart enough and inspired enough that we will achieve commercial fusion. It absolutely is going to happen. And I think the plans that I’ve seen from companies leading in that space are very, very realistic, but we’re on it on a charge.

The opportunity we see is in simplification, acceleration. It’s a brilliant opportunity for us as a business. We have the expertise in that machine space. We designed, built, and we operate every day the second largest pulse power machine in the world. So we absolutely want to be connected at that top table level, but as an enabling technology, we do believe we have a huge amount to offer.

Lead Reporter of Ignition